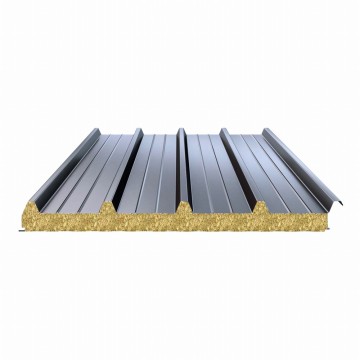

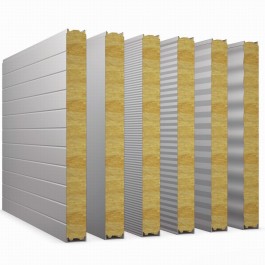

1:Parameters for Rock Wool Sandwich Roof Panels

| Steel Outer Layer | Common T (mm) | Outer Panel Specs 0.6-0.8(Coated Steel Panel) |

| Inner Panel Specs 0.4-0.7(coated steel panel) | ||

| Common L (mm) | ≤12,000 | |

| Common W (mm) | 500-1,100 | |

| Coating | PVDF/SRP/HDP/ PE | |

| Insulation Core | Core Material | High-density thermal insulation, fireproof and |

| water-repellent rock wool/Glass Wool | ||

| VW (kg/m³) | Rock Wool: ≥120/Glass Wool: ≥64/PU (Edge Sealing):≥38 | |

| Thickness (mm) | 50-150 | |

| TC (w/m·k) | Rock Wool:≤0.043 /Glass Wool:≤0.042 | |

| Fire Rating | Rock Wool: Class A /Glass Wool: Class A | |

| Process | Joint | 2-sided joint-Male-Female Joint, PU Edge Sealing |

| Production Process | Continuous Production Process | |

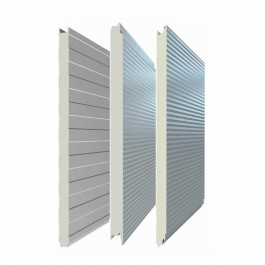

| Surface Texture | Flat/Embossed Pattern/Micro Ripple/V8 RIPPLE | |

| Center Trim Treatment | Metal Snap-in Cover Plate | |

| Upper steel plate style | 3 Peaks | |

| Joining method | Over Lap |

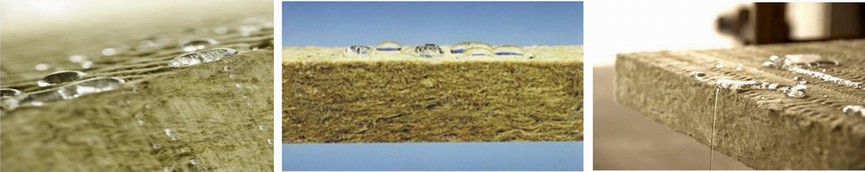

2:High Qulity Rock Wool Raw Materials Characteristics-Water Resistence

Mineral wool (rock wool) can achieve waterproof and moisture-proof functionality by adding water-reducing agents. However, when the content of alkali metal oxides is high in mineral wool (low acidity coefficient), it increases the water absorption in humid environments. Key indicators to focus on include:

-Mass moisture absorption rate

-Volume moisture absorption rate

-Water-reducing rate

-Short-term and long-term water absorption

-No capillary penetration

-Moisture resistance factor

With a water-reducing rate of 99.9% and a unique fiber random distribution structure that prevents water penetration, the highest water-reducing performance is achieved. High-quality rock wool with excellent water repellency has very low moisture absorption. According to tests, the mass moisture absorption rate is less than 0.5%, volume moisture absorption rate is less than 0.1%, water-reducing rate is equal to or greater than 99.6%, and short-term and long-term water absorption are both very low, generally below 1kg/m2, with no capillary penetration.

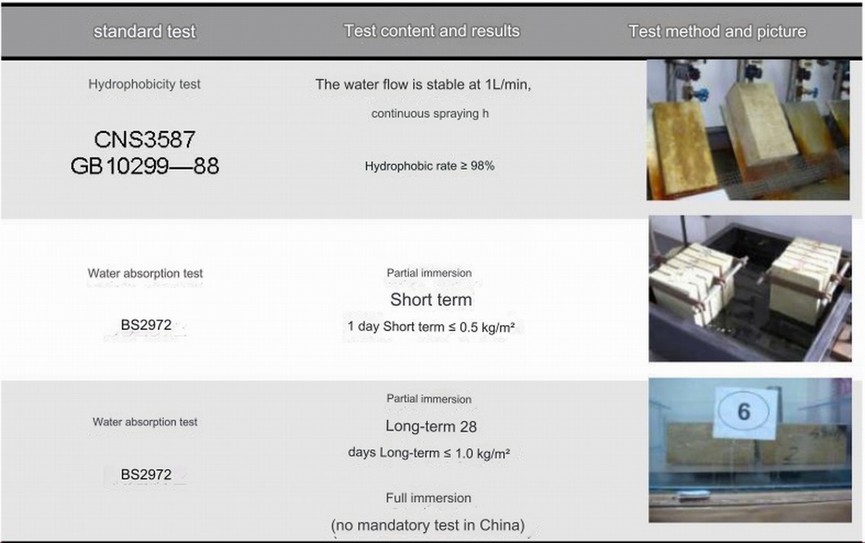

3:Professional Test of Water Resistence for High Qulity Rock Wool

Professional testing of water resistance for high-quality rock wool that we use follows specific standards and includes various tests and results.

According to CNS3587 and GB10299-88 standards, the water-reducing rate test involves maintaining a stable water flow of 1L/min and continuous spraying for 1 hour. The minimum requirement for the water-reducing rate is ≥98%.

The water absorption test, conducted based on BS2972 standard, includes partial immersion for short-term testing (1 day) and full immersion for long-term testing (28 days). The maximum water absorption for short-term testing is ≤0.5kg/m2, while for long-term testing, it is ≤1.0kg/m2.

4:Rock Wool Sandwich Roof Panels Production Line

5:Rock Wool Sandwich Roof Panels Project Cases

The High-Quality Water Resistant Rock Wool Sandwich Roof Panels have been successfully implemented in numerous project cases, demonstrating their exceptional performance in challenging environments. These panels provide excellent water resistance, preventing water ingress and ensuring long-term durability. The project cases showcase their reliability in withstanding heavy rain, extreme weather conditions, and high humidity. With their superior thermal insulation properties, these panels contribute to energy efficiency and create a comfortable indoor environment. From commercial buildings and warehouses to residential complexes and industrial facilities, the water-resistant rock wool roof panels have proven to be a reliable choice for projects requiring robust water protection.