1:Descriptions for Prefabricated Steel Structure Buildings

| Main Structure | Welded H Section or Hot Rolled H Section Steel |

| Purlin | C Section or Z section,Q235B,Q345B |

| Cladding system | Sandwich panels for wall and roofing,single sheets for wall and roofing |

| Roof/Wall Caldding | Corrugated Plate,or Sanwich panels for fireproof,insulation requirements,can choose EPS,PU/PIR,Rock Wool sandwich panels. |

| Brace | Q235B/Q345B Round Steel Tube/Angel steel/steel pipe |

| Tie Bar | Q235B/Q355B Round Steel Tube |

| Roof gutter | Galvanized color sheets or SS steel |

| Parapet | Designed as the customers' requirements. |

| Rain Spout | PVC pipes |

| Covering/Flashing | Bending parts from the galvanized color sheets to cover the edges. |

| Windows | Glass curtain,normal windows,Plastic windows,Aluminum Alloy windows,double glazed windows,fixed windows,opened windows,as your requirements |

| Skylight | PVC Skylight Panels |

| Ventilation | Ventilators, louvers |

| Doors | KFC doors,Glass doors,Swing door,Fire Exit doors,sandwich sliding doors,rolling doors,Electric rolling doors. |

| Connectiong | High strength Bolts,Normal Bolts,Anchor bolt |

| Packings | Suitable for shipping packaging,pallets, 40HQ, 40GP, according to your requirements. |

| Accessories | All screws,sealant,glue |

2:Steel Structure Production Production Process

The assembly process is a crucial factor in assessing the capabilities of a steel fabrication plant. It involves the use of templates or diagonal construction techniques, and in some cases, pre-assembly methods are employed. This process requires strong visual recognition skills and is a key determining factor for successful on-site installation.

Proper assembly ensures the accurate alignment and fitting of steel components, ensuring structural integrity and stability. A fabrication plant's ability to execute the assembly process efficiently reflects its expertise and proficiency in handling complex steel structures. By employing precise measurement and meticulous attention to detail, the plant ensures that the assembled components fit together seamlessly, facilitating smooth on-site installation and timely project completion.

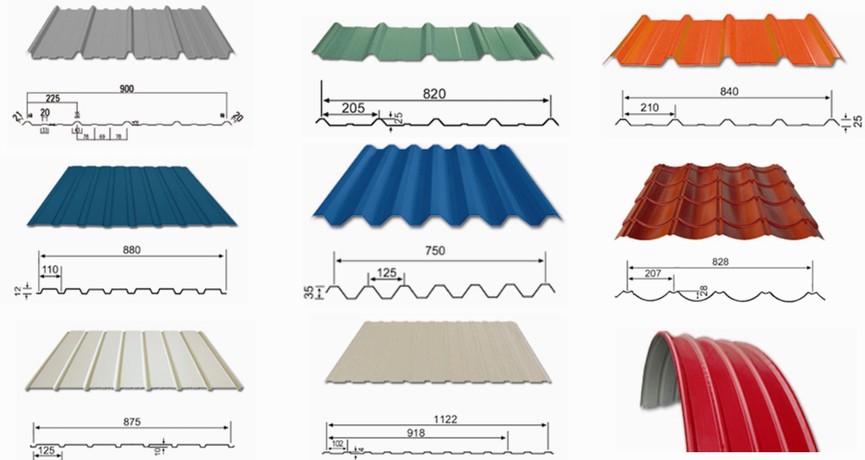

3:The Envelope Systems of Steel Buildins-Single Steel Sheet Wall Systems

Single steel sheet roof systems are an integral part of the envelope systems in steel buildings. These systems consist of a single layer of steel sheeting that serves as the primary roofing material. The steel sheets are typically made of galvanized steel or other corrosion-resistant materials to ensure durability and longevity. They are designed to provide excellent weather protection, insulation, and structural support to the building. Single steel sheet roof systems are known for their simplicity, cost-effectiveness, and ease of installation. They are commonly used in various types of steel buildings, including warehouses, industrial facilities, and agricultural structures.

4:Steel structure engineering accessory system:

4:Structural Steel Construction for Car 4s shop Project Cases

Structural steel construction is widely used in car 4S shop projects due to its numerous advantages. The strength, durability, and flexibility of structural steel make it an ideal choice for constructing the spacious showrooms and service areas required in car 4S shops. Steel structures allow for large open spaces, facilitating the display of vehicles and providing a comfortable environment for customers. Additionally, steel buildings can be easily customized and expanded to accommodate future growth or changes in the shop's layout. With efficient construction processes and cost-effective solutions, structural steel construction ensures the timely completion and successful operation of car 4S shop projects.

Next: Steel Structure Modular Cleanrooms for Pharmaceutical Processing