1:Descriptions for Prefabricated Steel Structure Buildings

| Main Structure | Frame Structure/Beam and Column Structure/Space Grid Structure/Truss Structure |

| Purlin | C Section or Z section,Q235B,Q345B |

| Cladding system | Sandwich panels for wall and roofing,single sheets for wall and roofing |

| Roof/Wall Caldding | Corrugated Plate,or Sanwich panels for fireproof,insulation requirements,can choose EPS,PU/PIR,Rock Wool sandwich panels. |

| Brace | Q235B/Q345B Round Steel Tube/Angel steel/steel pipe |

| Tie Bar | Q235B/Q355B Round Steel Tube |

| Roof gutter | Galvanized color sheets or SS steel |

| Parapet | Designed as the customers' requirements. |

| Rain Spout | PVC pipes |

| Covering/Flashing | Bending parts from the galvanized color sheets to cover the edges. |

| Windows | Glass curtain,normal windows,Plastic windows,Aluminum Alloy windows,double glazed windows,fixed windows,opened windows,as your requirements |

| Skylight | PVC Skylight Panels |

| Ventilation | Ventilators, louvers |

| Doors | KFC doors,Glass doors,Swing door,Fire Exit doors,sandwich sliding doors,rolling doors,Electric rolling doors. |

| Connectiong | High strength Bolts,Normal Bolts,Anchor bolt |

| Packings | Suitable for shipping packaging,pallets, 40HQ, 40GP, according to your requirements. |

| Accessories | All screws,sealant,glue |

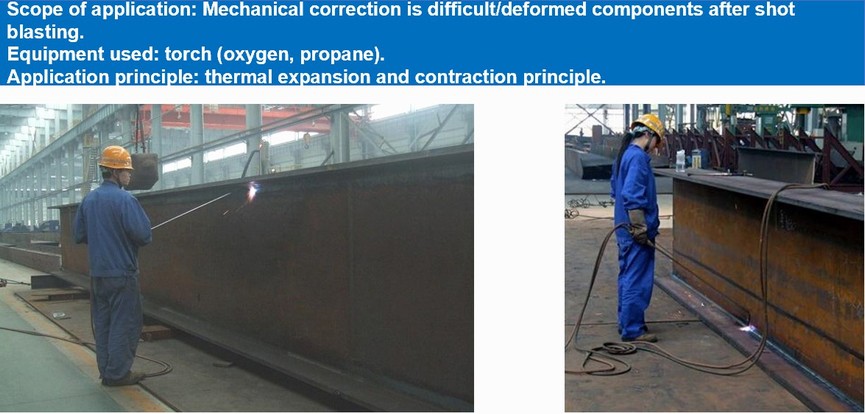

Flame correction is a crucial yet often overlooked process in steel structure production. It is specifically used for correcting difficult or deformed components that have undergone shot blasting. The equipment utilized in this process includes a torch fueled by oxygen and propane. The principle behind flame correction is based on the concept of thermal expansion and contraction. By strategically applying heat to specific areas, the metal can be manipulated to correct deformities and restore its intended shape. This process requires skilled operators with a keen understanding of metal properties and the ability to assess and address structural deformities. It is an important factor in evaluating the capabilities of a fabrication facility.

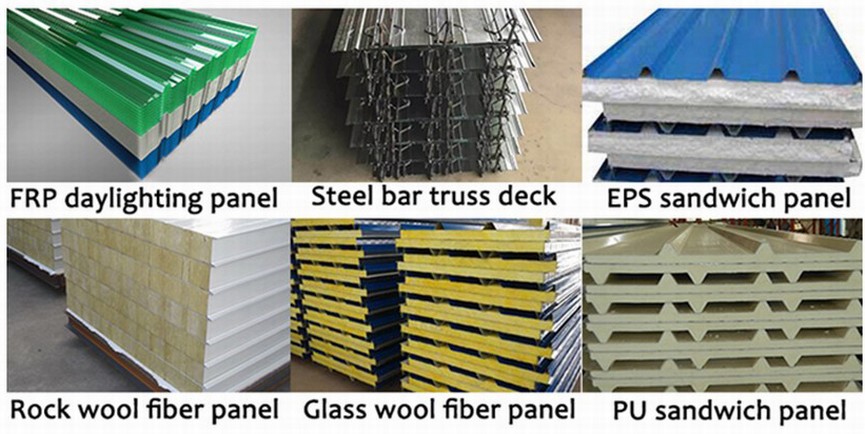

3:The Envelope Systems of Steel Buildings-Steel Sandwich Panel Systems

Steel sandwich panel systems are available in various classifications, including PU (Polyurethane), rock wool, glass wool, and EPS (Expanded Polystyrene). Each classification offers unique properties and benefits for different applications.

PU (Polyurethane) sandwich panels provide excellent thermal insulation and are commonly used in buildings requiring high energy efficiency.

Rock wool sandwich panels offer superior fire resistance and sound insulation, making them suitable for industrial and commercial buildings.

Glass wool sandwich panels have excellent thermal and acoustic insulation properties, making them ideal for applications where enhanced energy efficiency and soundproofing are desired.

EPS (Expanded Polystyrene) sandwich panels are lightweight and cost-effective, suitable for a wide range of building applications.

These different classifications of metal sandwich panels provide options to meet specific project requirements, ensuring optimal performance, durability, and comfort in steel buildings.

4:Design, Production and Storage of Steel Structures

Production: Steel structures are fabricated in specialized workshops using advanced machinery and equipment. Skilled technicians and welders execute the fabrication process, which includes cutting, drilling, welding, and surface treatment. Quality control measures ensure the precision and integrity of the fabricated components.

Storage: After production, steel components are carefully stored in designated areas. They are protected from environmental factors such as moisture and corrosion. Proper storage ensures that the components remain in optimal condition until they are transported to the construction site.

5:Steel Frame R&D Center Buidling Project Cases

Steel frame R&D center building projects showcase the innovation and expertise in steel structure construction. These projects serve as dedicated spaces for research, development, and testing of steel structures. The buildings are designed to provide flexible and efficient spaces, accommodating various functions such as laboratories, offices, meeting rooms, and exhibition areas. With a focus on sustainability and energy efficiency, these structures incorporate advanced technologies and materials. The R&D center buildings demonstrate the capabilities of steel structures in creating modern, functional, and environmentally friendly spaces for scientific research and technological advancements.

Next: Steel Structure Hospital Buildings with ISO