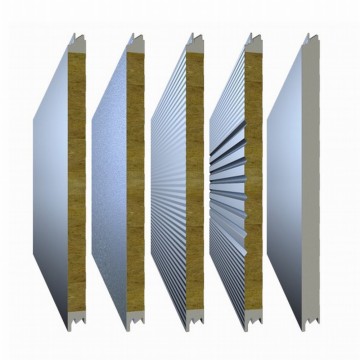

1:Parameters for Rock Wool Sandwich Wall Panels

| Steel Outer Layer | Common T (mm) | Outer Panel Specs 0.6-0.8(Coated Steel Panel) |

| Inner Panel Specs 0.4-0.7(coated steel panel) | ||

| Common L (mm) | ≤12,000 | |

| Common W (mm) | 500-1,100 | |

| Coating | PVDF / SRP / HDP / PE | |

| Insulation Core | Core Material | High-density thermal insulation, fireproof and |

| water-repellent rock wool/Glass Wool | ||

| VW (kg/m³) | Rock Wool: ≥120/Glass Wool: ≥64/PU (Edge Sealing):≥38 | |

| Thickness (mm) | 50-150 | |

| TC (w/m·k) | Rock Wool: ≤ 0.043 / Glass Wool: ≤ 0.042 | |

| Fire Rating | Rock Wool: Class A / Glass Wool: Class A | |

| Process | Profile | 2-sided joint-Male-Female Joint, PU Edge Sealing |

| Production Process | Continuous Production Process | |

| Surface Texture | Flat / Embossed Pattern/ Micro Ripple / V8 RIPPLE | |

| Center Trim Treatment | Metal Snap-in Cover Plate |

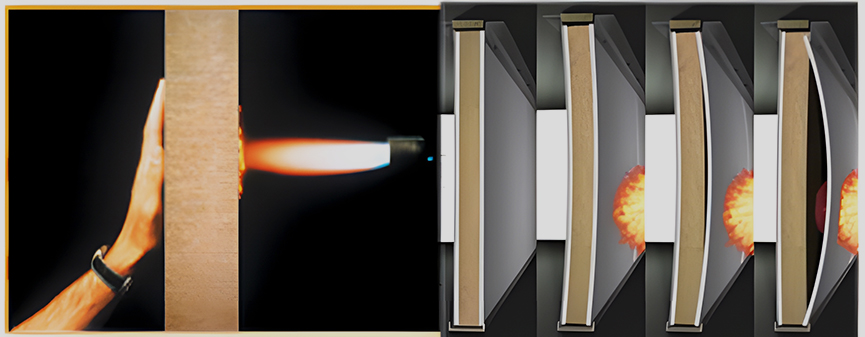

2:High Quality Rock Wool High Temperature Resistance

Rock Wool Wall Sandwich Panels with PU Edge Sealing feature a non-combustible core material with a melting point that can exceed 1000 degrees Celsius. They offer a maximum fire resistance limit of up to 4 hours, generating minimal smoke and harmful gases during combustion. With a sealed joint design, they provide high-level fire protection. Even at high temperatures, the bond between the rock wool and steel sheet on the non-fire side remains intact. Available in various sizes and thicknesses, these panels can accommodate different fire resistance levels for exterior wall applications.

3:Sandwich Panels Production Machine-Automatic Cutting Machine

Automatic Cutting Machine for Sandwich Panels offers precise and efficient cutting capabilities. With an automatic cutting length ranging from 2m to 16m (typically), it provides flexibility to meet various project requirements. Equipped with a cold bed system, the machine effectively dissipates internal heat from the core material, ensuring uniform heat distribution and enhancing the overall quality of the panels. The automated cutting process streamlines production and improves productivity. Experience superior results with our cutting-edge machine, delivering high-quality sandwich panels for a wide range of applications.

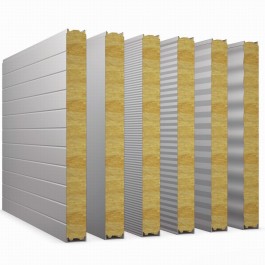

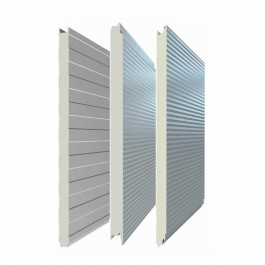

4:Details of Rock Wool Wall Sandwich Panels with PU Edge Sealing

5:Rock Wool Wall Sandwich Panels with PU Edge Sealing Project Cases

Our collection of project cases showcases the exceptional performance and versatility of Rock Wool Wall Sandwich Panels with PU Edge Sealing. These cases highlight successful installations in various industries, including commercial, industrial, and residential buildings. The panels' high-quality construction, combined with the PU edge sealing, ensures superior insulation, fire resistance, and durability. Each case demonstrates the panels' impeccable flatness, precise interlocking joints, and high joint strength, resulting in seamless and visually appealing exteriors. With our Rock Wool Wall Sandwich Panels with PU Edge Sealing, we have consistently delivered outstanding solutions that meet the unique requirements of each project, leaving our clients highly satisfied with the quality and performance of their buildings.

Next: Heavy Duty Metal Warehouse Buildings for Logistics Park