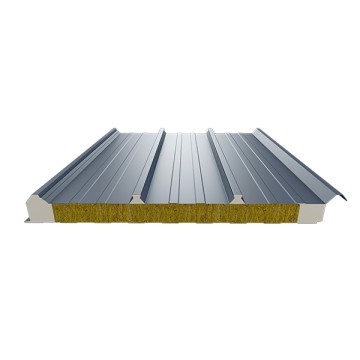

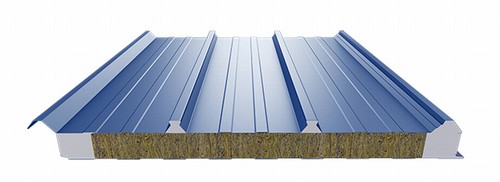

1:Parameters for Rock Wool Roof Sandwich Panel with PU Edge Sealing

| Steel Outer Layer | Common T (mm) | Outer Panel Specs 0.6-0.8(Coated Steel Panel) |

| Inner Panel Specs 0.4-0.7(coated steel panel) | ||

| Common L (mm) | ≤12,000 | |

| Common W (mm) | 500-1,100 | |

| Coating | PVDF/SRP/HDP/ PE | |

| Insulation Core | Core Material | High-density thermal insulation, fireproof and |

| water-repellent rock wool/Glass Wool | ||

| VW (kg/m³) | Rock Wool: ≥120/Glass Wool: ≥64/PU (Edge Sealing):≥38 | |

| Thickness (mm) | 50-150 | |

| TC (w/m·k) | Rock Wool:≤0.043 /Glass Wool:≤0.042 | |

| Fire Rating | Rock Wool: Class A /Glass Wool: Class A | |

| Process | Joint | 2-sided joint-Male-Female Joint, PU Edge Sealing |

| Production Process | Continuous Production Process | |

| Surface Texture | Flat/Embossed Pattern/Micro Ripple/V8 RIPPLE | |

| Center Trim Treatment | Metal Snap-in Cover Plate | |

| Upper steel plate style | 3 Peaks | |

| Joining method | Over Lap |

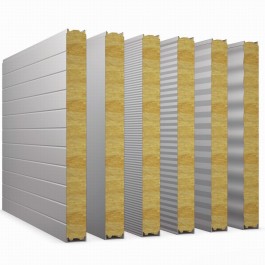

2:Details of Rock Wool Roof Sandwich Panel with PU Edge Sealing

The Rock Wool Roof Sandwich Panel with PU Edge Sealing offers a combination of fire resistance and enhanced interlocking strength with the PU-filled joint interface. These panels provide excellent thermal insulation and fireproofing properties, ensuring a safe and energy-efficient roofing solution. The PU edge sealing enhances the joint strength between the panels, preventing water leakage and improving overall structural integrity. With its advanced design, this panel system offers reliable performance and durability, making it suitable for a wide range of applications in commercial, industrial, and residential buildings.

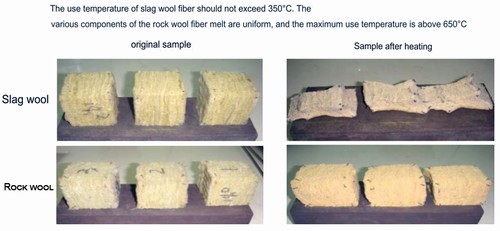

3:High Temperature Resistant Rock Wool

The performance of rock wool insulation is influenced by several factors. Firstly, strength is determined by the diameter of individual fibers, with finer fibers exhibiting higher tensile strength. However, high alkaline content can reduce strength. Relevant indicators include compressive strength and tensile strength. Secondly, chemical stability and durability are crucial, with higher acidity coefficients indicating better durability. Fire resistance, assessed through standards like GB/T9978.1-2008, evaluates integrity and thermal insulation. Moisture absorption, water resistance, and hydrophobic properties are influenced by factors such as the content of calcium oxide and magnesium oxide, as well as the performance of the binding agent. Lastly, market acceptance is influenced by stable physicochemical properties, competitive pricing, and the availability of raw materials.

4:Sandwich Panels Production Machine-Automatic Cutting Machine

5:Rock Wool Roof Sandwich Panel with PU Edge Sealing Project Cases

Rock Wool Roof Sandwich Panels with PU Edge Sealing have been successfully implemented in various project cases. These panels provide excellent thermal insulation, fire resistance, and waterproofing properties, making them ideal for roofing applications. The PU edge sealing enhances the panel's structural integrity and prevents water leakage. The project cases showcase the panels' versatility and suitability for different architectural designs and construction requirements. They have been used in commercial buildings, industrial facilities, residential complexes, and more. The successful implementation of Rock Wool Roof Sandwich Panels with PU Edge Sealing demonstrates their reliability, durability, and performance in real-world applications.

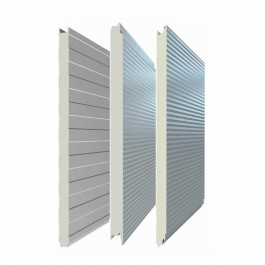

Next: Rock Wool Wall Sandwich Panels with PU Edge Sealing