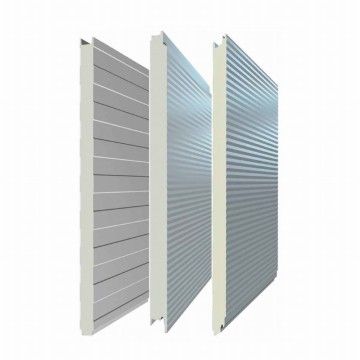

1:Parameters for PU PUR PIR Polyurethane Sandwich Wall Panels

| Steel Outer Layer | CommonT(mm) | Specs0.5-0.8(Coated Steel Panel) |

| Specs0.46-0.7(Stainless Steel | ||

| CommonL(mm) | ≤15,000 | |

| Common W(mm) | 930-1130 | |

| Coating | PVDF/HDP/PE | |

| Insulation Core | Core Material | PU |

| VW(kg/m³) | PU: 40±2 | |

| Thickness(mm) | 50-200 | |

| UValue(w/mk) | PU:≤0.024 | |

| Fire Rating | PU:CLASS B1 | |

| Process | Joint | 2-sidedioint-Male-FemaleJoint |

| Production Process | Continuous Production Process | |

| Surface Texture | Flat/Straight Bead/MicroRipple | |

| Center Trim Treatment | PU Filling+Decorative Cover | |

2:Descriptions of Exceptional PU PUR PIR Polyurethane Sandwich Wall Panels

PU PUR PIR Polyurethane Sandwich Wall Panels are produced through a chemical reaction between polymeric MDI black material and composite white material, followed by foaming in production equipment. The current density of polyurethane panels ranges from 40-50 kg/m³, with fire retardant levels classified as B1, B2, and B3. These panels find extensive applications in the insulation industry, including refrigerators, freezers, cold storage rooms, refrigerated trucks, pipes, building exteriors, roofs, workshops, factories, and public buildings. They provide excellent thermal insulation, contributing to energy efficiency and creating a controlled environment for various purposes.

3:Raw materials of PU PUR PIR Polyurethane Sandwich Wall Panels

The raw materials of PU PUR PIR Polyurethane Sandwich Wall Panels include black material, white material, n-pentane, catalysts (134 and 93360), and adhesive 1962. Black material is stored in cans, with 5 cans in the cold chain workshop and 2 cans in the Lecai workshop. White material is also stored in cans, drums, or barrels, with only 1 can in the cold chain workshop, primarily in drums for large quantities like 511, while smaller quantities like 1141 and 501 are procured based on orders in drums or barrels. N-pentane is typically stored in cans, but due to stability issues, barrels are used as a supplementary option. Catalysts (134 and 93360) and adhesive 1962 are stored in barrels.

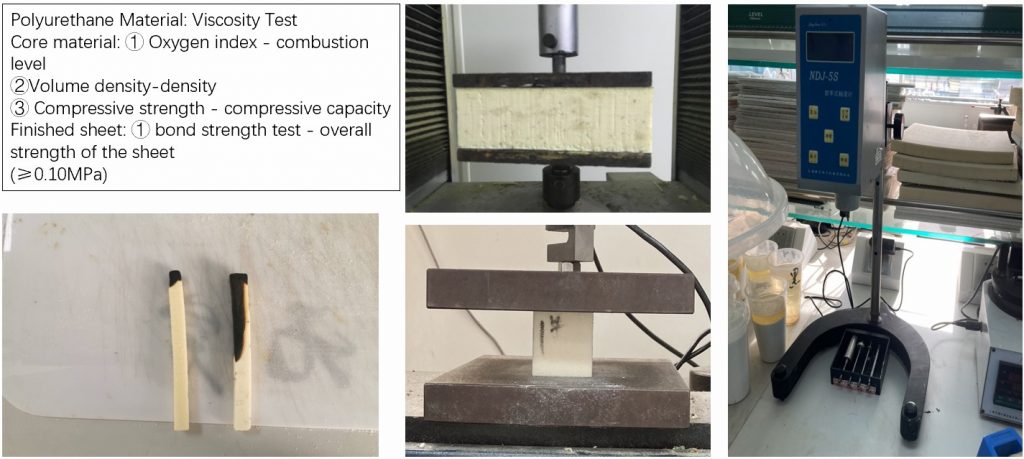

4:Laboratory Quality Testing of PU PUR PIR Polyurethane Sandwich Wall Panels

5:PU PUR PIR Polyurethane Sandwich Wall Panels Project Cases

Our collection of project cases showcases the successful applications of PU PUR PIR Polyurethane Sandwich Wall Panels. These cases highlight a wide range of projects in various industries, including commercial, industrial, and residential buildings. The panels' superior thermal performance, fire resistance, and durability have been instrumental in creating energy-efficient and comfortable spaces. Each case demonstrates the panels' excellent bond strength, density, and compressive strength, ensuring their long-term structural integrity. With our PU PUR PIR Polyurethane Sandwich Wall Panels, we have consistently delivered exceptional solutions that meet the unique requirements of each project, leaving our clients highly satisfied with the performance and aesthetics of their buildings.

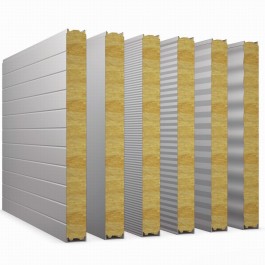

Next: High-Quality Rock Wool Sandwich Panel for Exterior Wall Insulation