1:Descriptions for Metal Warehouse Buildings

| Product name | Pre-Engineered Steel Frame Buildings for Electronics Factory |

| Main Structure | Weld H steel/ Steel Beam/Column |

| Sub-Structure | C/Z purlin,C/Z section steel |

| Roofing&Wall | Fireproof/Insulated sandwich panels or corrugated steel plate |

| Connect | By bolts |

| Lighting system | Lighting panel/aluminum alloy window/sliding window/plastic steel window/aluminum window with thermal insulation broken bridge |

| Ventilation System | Stainless Steel Ventilator |

| Door | Composite door/sliding door/rolling door/swing door/Industrial lift door |

| Certificate | CE/ISO9001/ISO14001 |

| Application | Workshop/Warehouse/Storage/Frame/Shed/Any Steel Structure Buildings |

2:Steel Structure Production Production Machines

Gantry welding is a primary equipment used for the welding and shaping of H-beams in the construction industry. It utilizes submerged arc welding wire and flux, which are essential auxiliary materials for the welding process. Gantry welding can be categorized into different types based on the specific components being welded. This includes welding H-beams using gantry welding, welding box structures using gantry welding, and employing gantry electroslag welding techniques. Additionally, there are variations in the number of welding wires used, such as single-wire, double-wire, and multiple-wire configurations, which offer flexibility in the welding process.

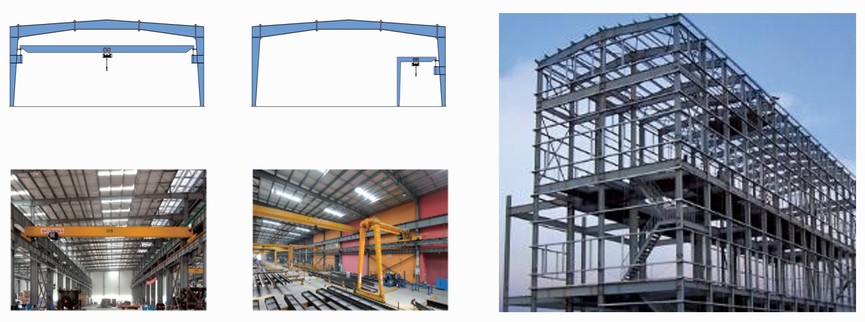

3:Two portal steel workshop frame types with cranes

2 common types of portal steel workshop frames that are equipped with cranes: single-span and multi-span structures.

Single-Span Workshop Frame with Crane:

This type of workshop frame consists of a single-span structure supported by columns on both ends. It provides a large open space for efficient movement of cranes and equipment. The crane is typically installed on the top of the frame, allowing it to traverse along the span and lift heavy loads with ease. Single-span workshop frames with cranes are widely used in industries that require a spacious working area and the capability to handle substantial loads.

Multi-Span Workshop Frame with Crane:

Multi-span workshop frames are designed with multiple spans connected by intermediate columns. This type of structure offers flexibility in layout and allows for the integration of different work areas. The crane system is installed on the main beams or trusses, providing lifting capabilities across multiple spans. Multi-span workshop frames with cranes are commonly utilized in industries where various operations need to be conducted simultaneously or where specific workflow arrangements are required.

4:Steel Structure Loading and Shipping:

Loading and shipping steel structure members is a crucial process in the construction industry. Steel members, such as beams, columns, and trusses, are carefully loaded onto transportation vehicles for delivery to the construction site. During the loading process, proper lifting equipment and techniques are employed to ensure the safety and integrity of the steel members. Once loaded, the steel members are securely fastened and protected to prevent damage during transportation. Efficient logistics and coordination are essential to ensure timely and accurate delivery of the steel structure members. By adhering to strict loading and shipping protocols, the construction industry can ensure the smooth and successful assembly of steel structures.

Next: Structural Steel Construction for Chemical Industry