Technical indicators:

1.Substrate

Supply according to JIS g3302 or gbu518 standard.

2.Coating: Z30, Z40, Z60, Z80, az30, AZ40, AZ60, AZ80Coating

Color coating: in accordance with the national standard GB / t12754 developed more stringent internal control standard supply.

Coating varieties: internal and externaTl polyester, silicon modified polyester, high durability polyester, epoxy resin, alkyd resin, ethylene resin, polypropylene, polyvinylidene fluoride, fluorocarbon.

Coating color: according to the user's needs.

Coating structure: 2/12/2

Coating thickness: 20um for the upper surface and 5-15um for the lower surface, or according to the user's requirements.

Parameters:

| 规格(MM) Size(mm) | |||

| 厚度Thickness | 0.12-1.5MM | 基板Base plate | 热浸镀锌板Hot-dipped galvanized steel sheet热镀铝锌硅板Hot-dipped aluminum zinc steel sheet |

| 宽度width | 700-1250MM | 颜色Color | 老尔色卡颜色或者根据色样RAL card no.or color samples |

| 涂层Coating | 两涂两烘Two coating and two drying | 面漆漆膜厚度Top coating | 5+10-20UM |

| 面 Top side | 两涂两烘Two coating and two drying | 背漆漆膜厚度Back coating | 5-12um |

| 背Back side | 一涂一烘one coating and one | 卷内径COIL ID | 508/610MM |

| 60%光泽度60%Glossy | 高>70 中40-70 低<40 | 铅笔硬度Pencil hardness | >>2H |

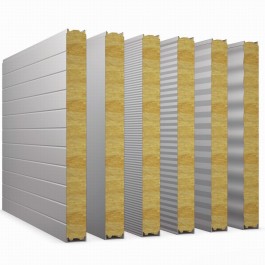

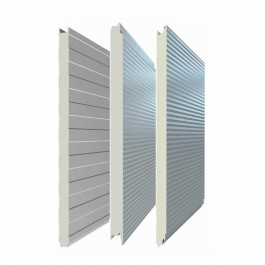

Color coated steel plate, referred to as "color coated plate", refers to the product made by coating one or two layers of organic coating (or more than two layers if necessary) on the surface of the substrate by continuous roller coating after surface pretreatment, and then baking.

The coating quality of color coated steel plate is far more uniform, stable and ideal than that of single piece spraying or brushing on the formed metal surface. The color coated steel plate has excellent decoration, formability, corrosion resistance and strong coating adhesion, which can keep the color novel for a long time. Due to the mechanical strength and easy forming performance of the steel plate, as well as the good decoration and corrosion resistance of organic materials, the color coated steel plate has achieved good economic benefits such as efficient construction, energy saving, and pollution prevention caused by secondary processing. It has become an ideal composite material in the construction, household appliances, light industry, mechanical and electrical products and other industries.

application area

----Application in architecture

Outdoor construction industry mainly includes: roof, roof structure, balcony panel, window frame, gate, garage door, rolling shutter door, sales booth, shutter, guard house, simple room, waiting room (kiosk), refrigerator car, etc;

The main indoor applications are: door, partition wall, door frame, light steel structure, sliding door, ceiling, screen, toilet interior, elevator interior, elevator lobby, etc.

---Applications in electrical appliances

Refrigerator, frozen food display cabinet, washing machine, electric oven, basin recorder, amplifier, vending machine, air conditioner, computer, copier, switch cabinet, instrument cabinet, electric fan, vacuum cleaner, etc.

---Application in transportation

Car ceiling, back plate, coaming, interior decorative panel, car shell, car box plate, car, dashboard, console shell, tram, train ceiling, partition, inner wall door, vehicle interior device, ship color separation plate, ship furniture, floor, container, etc.

----Application of platinum processing and furniture

Instrument shell, electronic organ, weight apparatus, dustbin, meter, instrument panel, thermos bottle shell, photographic equipment, typewriter, notice board, clock, lighter, packing container, etc.

Next: Nano anticorrosive board