1:Descriptions for Prefabricated Steel Structure Buildings

| Main Structure | Frame Structure/Beam and Column Structure/Space Grid Structure/Truss Structure |

| Purlin | C Section or Z section,Q235B,Q345B |

| Cladding system | Sandwich panels for wall and roofing,single sheets for wall and roofing |

| Roof/Wall Caldding | Corrugated Plate,or Sanwich panels for fireproof,insulation requirements,can choose EPS,PU/PIR,Rock Wool sandwich panels. |

| Brace | Q235B/Q345B Round Steel Tube/Angel steel/steel pipe |

| Tie Bar | Q235B/Q355B Round Steel Tube |

| Roof gutter | Galvanized color sheets or SS steel |

| Parapet | Designed as the customers' requirements. |

| Rain Spout | PVC pipes |

| Covering/Flashing | Bending parts from the galvanized color sheets to cover the edges. |

| Windows | Glass curtain,normal windows,Plastic windows,Aluminum Alloy windows,double glazed windows,fixed windows,opened windows,as your requirements |

| Skylight | PVC Skylight Panels |

| Ventilation | Ventilators, louvers |

| Doors | KFC doors,Glass doors,Swing door,Fire Exit doors,sandwich sliding doors,rolling doors,Electric rolling doors. |

| Connectiong | High strength Bolts,Normal Bolts,Anchor bolt |

| Packings | Suitable for shipping packaging,pallets, 40HQ, 40GP, according to your requirements. |

| Accessories | All screws,sealant,glue |

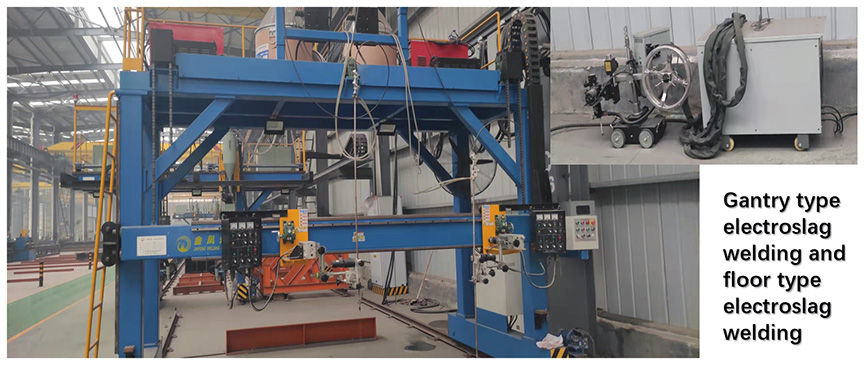

Steel Structure Electroslag Welding Equipment is used for joining thick steel components through the electroslag welding process. There are two common types: gantry type electroslag welding and floor type electroslag welding.

Gantry type electroslag welding utilizes a gantry system to support and move the welding head along the workpiece. It is suitable for welding large and heavy steel structures such as bridge girders and offshore platforms.

Floor type electroslag welding is performed on a horizontal surface, with the welding head fixed and the workpiece being moved underneath. It is commonly used for welding thick plates and structural components.

Both methods offer efficient and high-quality welding results, ensuring the strength and integrity of steel structures.

3:Steel Structure Production Process-Painting

Painting is an essential step in the steel structure production process. It involves the application of protective coatings to the steel components to enhance their durability, corrosion resistance, and aesthetic appearance.

The painting process begins with surface preparation, which includes cleaning, degreasing, and removing any rust or contaminants. Then, a primer coat is applied to promote adhesion between the steel surface and the topcoat. Finally, the topcoat is applied, which provides the desired color and finish.

Proper painting not only enhances the aesthetics of steel structures but also provides long-term protection against environmental factors. It ensures that the steel components maintain their integrity and longevity throughout their service life.

4:Multi-Story Steel Structure Supermarket Buildings Project Cases

Our portfolio of multi-story steel structure supermarket buildings showcases our expertise in delivering successful projects for retail businesses. These cases demonstrate our ability to design and construct efficient and attractive spaces that meet the unique requirements of supermarkets. From spacious retail areas to storage facilities and customer amenities, our projects prioritize functionality, durability, and aesthetic appeal. We work closely with clients to understand their specific needs and deliver customized solutions that optimize space utilization and create a pleasant shopping environment. With our commitment to quality construction and timely delivery, we have established a strong track record in the industry.

Next: Pre-Engineered Steel Hotel Buildings Near Me