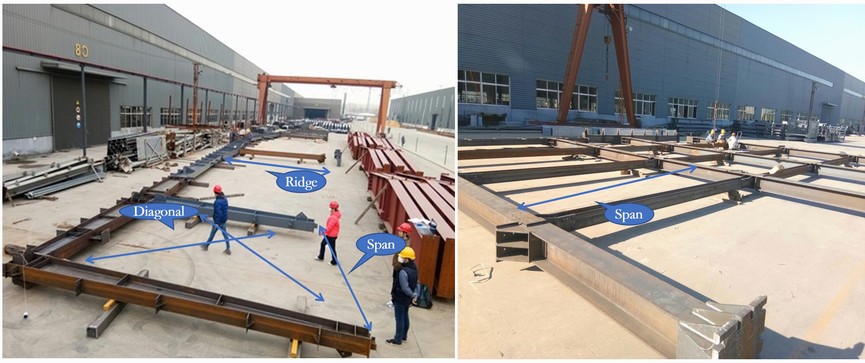

1:Descriptions for Prefabricated Steel Structure Buildings

| Main Structure | Frame Structure/Beam and Column Structure/Space Grid Structure/Truss Structure |

| Purlin | C Section or Z section,Q235B,Q345B |

| Cladding system | Sandwich panels for wall and roofing,single sheets for wall and roofing |

| Roof/Wall Caldding | Corrugated Plate,or Sanwich panels for fireproof,insulation requirements,can choose EPS,PU/PIR,Rock Wool sandwich panels. |

| Brace | Q235B/Q345B Round Steel Tube/Angel steel/steel pipe |

| Tie Bar | Q235B/Q355B Round Steel Tube |

| Roof gutter | Galvanized color sheets or SS steel |

| Parapet | Designed as the customers' requirements. |

| Rain Spout | PVC pipes |

| Covering/Flashing | Bending parts from the galvanized color sheets to cover the edges. |

| Windows | Glass curtain,normal windows,Plastic windows,Aluminum Alloy windows,double glazed windows,fixed windows,opened windows,as your requirements |

| Skylight | PVC Skylight Panels |

| Ventilation | Ventilators, louvers |

| Doors | KFC doors,Glass doors,Swing door,Fire Exit doors,sandwich sliding doors,rolling doors,Electric rolling doors. |

| Connectiong | High strength Bolts,Normal Bolts,Anchor bolt |

| Packings | Suitable for shipping packaging,pallets, 40HQ, 40GP, according to your requirements. |

| Accessories | All screws,sealant,glue |

2:Steel Structure Production Production Machine-CNC Drilling Machine

CNC drilling machine is a vital equipment used in the production process of steel structures. It is specifically designed to accurately drill holes in various steel components, such as beams, plates, and columns. The machine is equipped with computer-controlled systems that provide precise positioning and drilling capabilities, ensuring the accuracy and efficiency of the drilling process. With its automated features, the CNC drilling machine improves productivity, reduces labor costs, and enhances the overall quality of steel structure production.

3:Straightness of Steel Components - Inspection of Laser Correspondence

Straightness of steel components is a critical aspect in ensuring their structural integrity and performance. To inspect the straightness of these components, laser correspondence is often employed. Laser correspondence involves the use of laser measurement systems to assess the alignment and deviation of steel elements. By projecting a laser beam onto the surface of the component and analyzing the reflected pattern, precise measurements of straightness can be obtained. This inspection method allows for quick and accurate detection of any deviations from the desired straightness, enabling necessary adjustments or corrective actions to be taken during the fabrication process.

4:Muti-story Steel Structure Apartment Buildings Construction Site

4:Multi-StorySteel Structure Apartment Buildings Project Cases

The multi-story steel structure apartment buildings project cases showcase the successful implementation of modern architectural design and engineering expertise. These projects demonstrate the versatility, strength, and aesthetic appeal of steel structures in creating high-rise residential complexes. With efficient space utilization, flexible floor plans, and sustainable construction practices, these buildings offer residents comfortable and contemporary living spaces. The use of advanced construction techniques, such as prefabrication and modular construction, ensures faster project delivery and cost efficiency. From luxurious penthouses to affordable housing units, the multi-story steel structure apartment buildings project cases exemplify innovation, durability, and functionality in the realm of urban living.

Next: Customized Steel Structure School Buildings