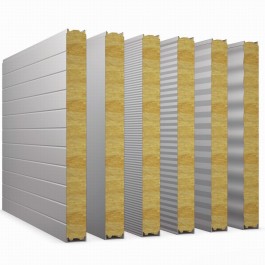

1:Parameters for Glass Wool Wall Sandwich Panels

| Effective width | Wall panel: 950mm 1150mm 1200mm; Roof panel: 950mm 980mm |

| Length | According to customer's request |

| Materials | Polystyrene foam board(EPS), Color steel sheet |

| Structure | Upper and lower layer: Color steel sheet |

| Middle: polystyrene foam board or polyurethane foam board | |

| Thickness | Color steel sheet: 0.3-0.6mm Polystyrene foam board: 50mm 75mm 100mm 150mm 200mm |

| The polystyrene density | 8-20kg/m3 |

| Conventional color | Ocean blue, tephrosious |

| Character | Light in weight, heat insulation, water resistant, green and environmental |

| Use | various roofs and walls referring to the large size factory buildings, storages, exhibition halls, gymnasiums etc. |

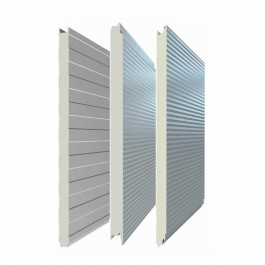

2:Descriptions of EPS Sandwich Panels

EPS (Expanded Polystyrene) Sandwich Panels offer exceptional insulation and lightweight construction. The panels consist of an EPS core sandwiched between two outer layers, typically made of galvanized steel or aluminum. These panels provide excellent thermal resistance, reducing heat transfer and maintaining comfortable indoor temperatures. Their lightweight nature makes them easy to handle and install, saving time and labor costs. EPS Sandwich Panels are widely used in various industries, including construction, cold storage, and prefabricated buildings. With their durability, energy efficiency, and versatility, EPS Sandwich Panels are a popular choice for projects that require efficient insulation and structural strength.

EPS Sandwich Panels are known for their excellent durability and longevity. The EPS core material is resistant to moisture, rot, and corrosion, ensuring that the panels maintain their structural integrity over time. They are also resistant to insects and pests, further enhancing their lifespan. The outer layers of galvanized steel or aluminum provide additional protection against weather elements, including UV radiation, rain, and wind. This combination of durability and weather resistance makes EPS Sandwich Panels suitable for both indoor and outdoor applications. Whether used in residential, commercial, or industrial settings, EPS Sandwich Panels offer a cost-effective and sustainable solution for insulation, energy efficiency, and architectural design.

3:EPS Sandwich Wall Panel Raw Materials-EPS Plate

EPS Metal Composite Panels are constructed using EPS foam plates as one of their key raw materials. EPS foam boards, with their lightweight and excellent thermal insulation properties, provide the core material for these composite panels. The EPS foam boards are sandwiched between two outer layers of metal, typically aluminum or steel, creating a sturdy and durable construction material. These panels offer a perfect combination of insulation, strength, and aesthetics, making them suitable for a wide range of applications, including wall cladding, roofing, and façade systems. With EPS foam boards as their foundation, EPS Metal Composite Panels deliver superior performance and energy efficiency.

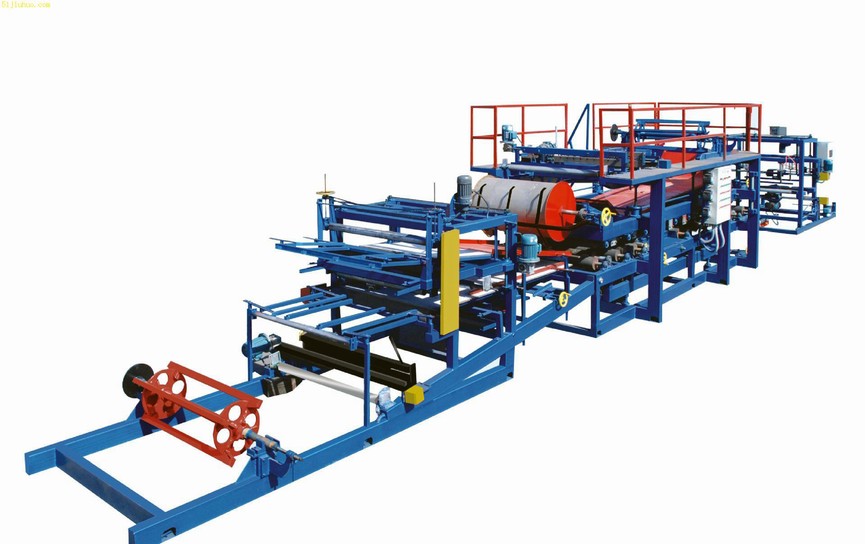

4:Production Line of EPS Sandwich Panels

5:EPS Sandwich Panels Project Cases

EPS Sandwich Panels are the perfect choice for construction projects such as modular container houses and light steel villas. These versatile panels offer excellent thermal insulation, energy efficiency, and structural integrity, ensuring comfortable and sustainable living spaces. In modular container houses, EPS Sandwich Panels are used for walls, roofs, and floors, providing superior insulation against heat, cold, and noise. They contribute to quick and efficient construction, allowing for easy assembly and customization. Similarly, in light steel villas, EPS Sandwich Panels offer durable and lightweight solutions for walls and roofs, enhancing energy efficiency and reducing construction time. Experience the benefits of EPS Sandwich Panels in creating innovative and eco-friendly housing solutions.

Next: Hign Quality Glass Wool Wall Sandwich Panels