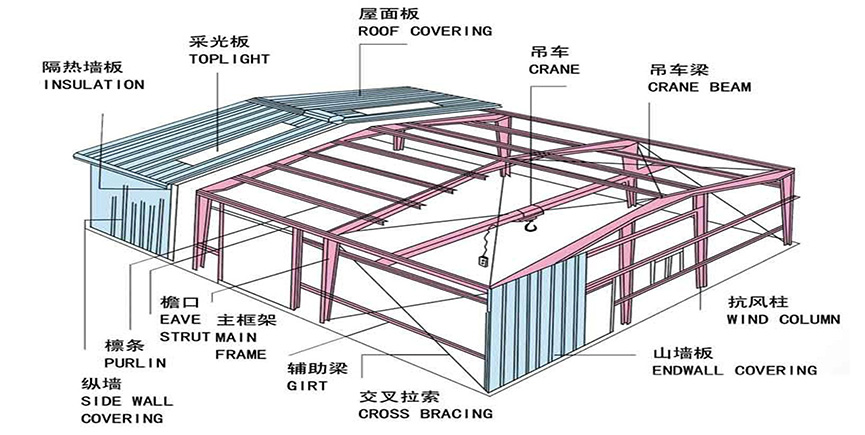

1:Descriptions for Prefabricated Steel Structure Buildings

| Main Structure | Welded H Section or Hot Rolled H Section Steel |

| Purlin | C Section or Z section,Q235B,Q345B |

| Cladding system | Sandwich panels for wall and roofing,single sheets for wall and roofing |

| Roof/Wall Caldding | Corrugated Plate,or Sanwich panels for fireproof,insulation requirements,can choose EPS,PU/PIR,Rock Wool sandwich panels. |

| Brace | Q235B/Q345B Round Steel Tube/Angel steel/steel pipe |

| Tie Bar | Q235B/Q355B Round Steel Tube |

| Roof gutter | Galvanized color sheets or SS steel |

| Parapet | Designed as the customers' requirements. |

| Rain Spout | PVC pipes |

| Covering/Flashing | Bending parts from the galvanized color sheets to cover the edges. |

| Windows | Glass curtain,normal windows,Plastic windows,Aluminum Alloy windows,double glazed windows,fixed windows,opened windows,as your requirements |

| Skylight | PVC Skylight Panels |

| Ventilation | Ventilators, louvers |

| Doors | KFC doors,Glass doors,Swing door,Fire Exit doors,sandwich sliding doors,rolling doors,Electric rolling doors. |

| Connectiong | High strength Bolts,Normal Bolts,Anchor bolt |

| Packings | Suitable for shipping packaging,pallets, 40HQ, 40GP, according to your requirements. |

| Accessories | All screws,sealant,glue |

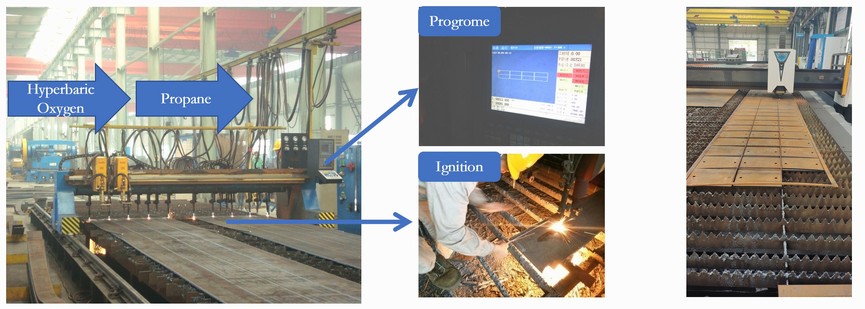

2:Steel Structure Production Production line

CNC cutting machine, is a commonly used equipment for material processing, specifically designed for cutting tasks. It is widely utilized in industrial production. The machine employs computer numerical control (CNC) to precisely control the movement of the cutting tool, enabling accurate cutting of various materials. It is commonly used for cutting wing plates, base plates, connecting plates, and other irregular-shaped components. While some manufacturing facilities opt for laser cutting or plasma cutting methods, CNC cutting machines remain popular due to their versatility and efficiency. Laser cutting offers high precision and can handle thin materials, while plasma cutting excels at cutting thicker materials. The choice of cutting method depends on specific application requirements, material types, cutting precision, and cost considerations.

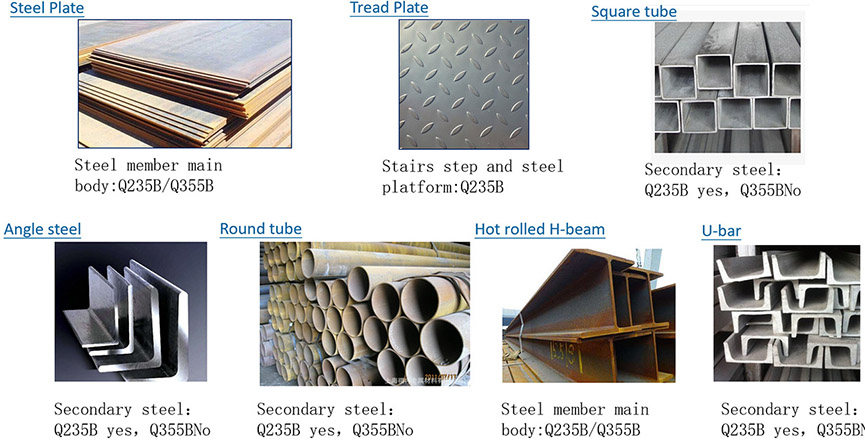

3:Steel Structure Raw Materials

Steel plates, patterned steel plates, rectangular tubes, angle steel, round tubes, hot-rolled H-beams, and channel steel, conforming to Chinese standards, are produced using high-quality raw materials. The main source of raw materials is iron ore, which undergoes extraction, crushing, and beneficiation processes to obtain iron concentrate. The iron concentrate is then smelted in blast furnaces, along with additives such as coke, limestone, and recycled steel scraps. The molten iron is further refined, alloyed, and cast into semi-finished products, which are subsequently hot-rolled, cold-rolled, or shaped into the desired steel products. The entire production process adheres to stringent quality control measures to ensure compliance with Chinese standards:Q235B/Q355B, etc.

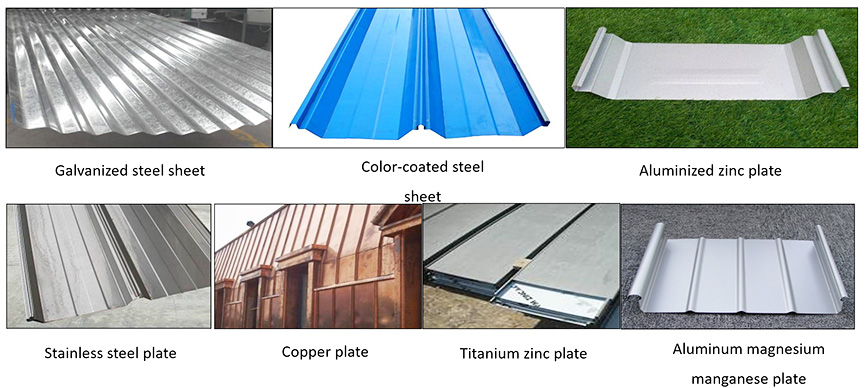

4:Different Metal Materials Used In Traditional Envelope Systems:

| Name | Ingredients | Performance description | Service life (general environment) | Fields of application |

| stainless steel | Contains chromium, nickel, titanium, silicon, aluminum, manganese, magnesium and other components | Beautiful surface, diversified use possibilities, corrosion resistance, high strength, high temperature resistance, fire resistance, simple maintenance, clean, high finish, good welding performance. | More than 50 years | Interior and exterior wall decoration panels, petroleum, chemical industry, water conservancy and electric power and other industries |

| Aluminized zinc plate | Coating composition: 55% aluminum and 43.4% zinc, 1.6% silicon composition. | Good heat resistance, corrosion resistance, good adhesion between coating and paint film, with good processing performance | 10-20 years | Roofs, walls, garages, modular houses, etc |

| Color coated board | Coating: PE, SMP, HDP, PVDF, polyvinyl fluoride - plastic solution | Pollution-free, economical, easy to process, easy to construct | 7-25 years | Walls, residential roofs, drainage ditches, downspouts, garage doors, etc |

| Aluminum magnesium manganese plate | Main alloying elements: | It has the advantages of light weight, high strength, corrosion resistance, good plasticity, easy processing and so on | More than 50 years | Roofing and façade materials |

| Manganese (1.0%-1.5%) | ||||

| Magnesium (0.8%-1.3%) | ||||

| Titanium zinc plate | Zinc: 99.995%, Copper: 0.08-1.0%, Titanium: 0.06-0.2% | It heals automatically after scratches, has a long service life, and does not require coating protection; It has good elongation and tensile strength, good plasticity. | 0.7mm roof 3°: 80-100 years | Public buildings, high-end residential roofs, roofs, curtain walls, etc |

| Vertical drainage: 200 years | ||||

| Metal plated | The surface is corrosion resistant and shows a corresponding metallic color | 30-80 years |

Next: Open Type Galvanized Steel Decking Sheets for Multi Rise Buildings