1:Parameters for Over Lap Type PIR PU PUF Roof Sandwich Panels

| Steel Outer Layer | Common Thickness(mm) | Outer Panel Specs 0.6-0.8(Coated Steel Panel) |

| Outer Panel Specs 0.4-0.7(Coated Steel Panel) | ||

| Common Length(mm) | ≤12000 | |

| Common Width(mm) | 950mm | |

| Coating | PVDF/SRP/HDP/PE | |

| Insulation Core | Core Material | PUR/PIR/Polyurethane/Polyisocyanurate Foam |

| Density(kg/M3) | ≥40; | |

| Thickness(mm) | 30-150 | |

| U value(w/m·k) | PU : ≤ 0.026 | |

| Fireproof Rating | Class B1,B2,B3 | |

| Process | Joint | 2-sided joint-Male-Female joint |

| Production Process | Continuous Production Process | |

| Surface Texture | Exterior side:3 waves Interior side:Flat/Flat Ribbing | |

| Center Trim Treatment | Connection | Metal Snap-in Cover Plate |

2:Details of Over Lap Type PIR PU PUF Roof Sandwich Panels

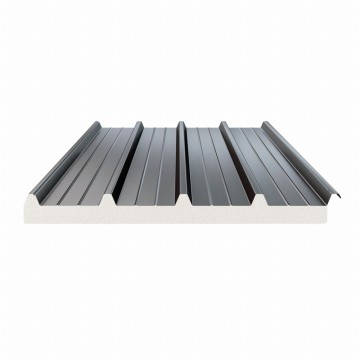

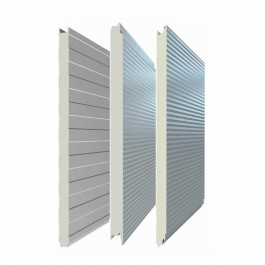

Over Lap Type PIR PU PUF Roof Sandwich Panels are a type of roofing material known for their exceptional thermal insulation and structural strength. These panels consist of a polyisocyanurate (PIR) or polyurethane (PU) foam core sandwiched between two layers of rigid facing material. The overlapping design ensures a tight and secure fit, minimizing the risk of water leakage. The panels are lightweight, easy to install, and provide excellent resistance to fire, moisture, and weathering. They are widely used in commercial, industrial, and residential buildings, offering reliable and efficient roofing solutions.

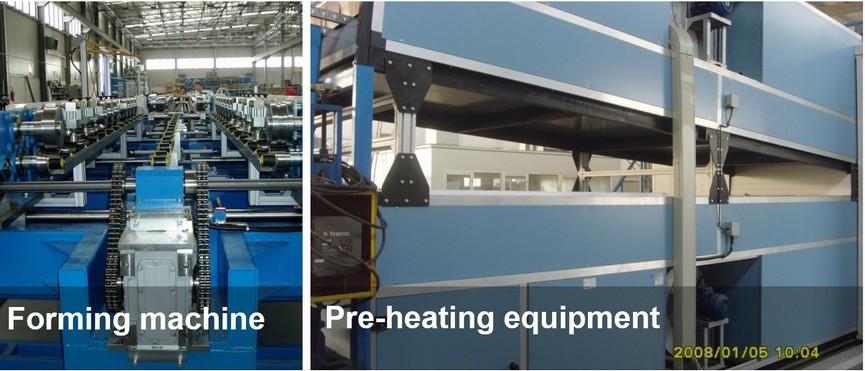

3:Over Lap Type PIR PU PUF Roof Sandwich Panels Production Machine

4:Quality Standard of PIR PU PUF Roof Sandwich Panels

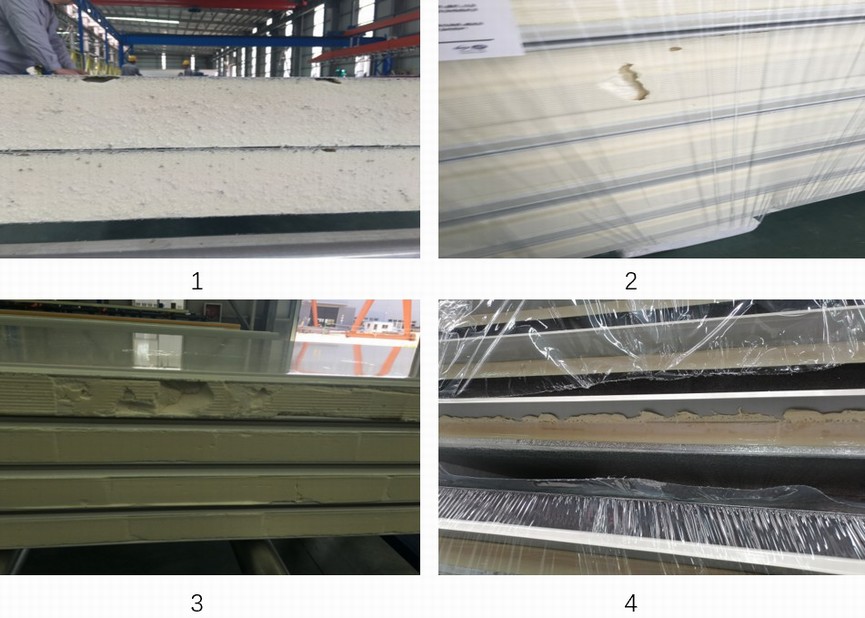

The cutting edges of PIR PU PUF roof sandwich panels should have a uniform PU foam distribution with no noticeable foam abnormalities. The panel pores should not exceed a depth of 5mm and a diameter of 3mm (Figure 1). The core material should have a smooth cut surface with no significant peeling, gaps, or foam abnormalities larger than 1cm in diameter (Figure 2). The tongue-and-groove joints should be free from any noticeable missing or protruding sections to ensure smooth interlocking (Figure 3, 4).

5:Over Lap Type PIR PU PUF Roof Sandwich Panels Installation Site

The installation site for Over Lap Type PIR PU PUF Roof Sandwich Panels is a crucial step in the construction process. These panels are designed to provide a durable and weather-resistant roofing solution. The installation process involves precise placement and secure fastening of the panels to ensure a tight fit and maximum performance. With proper installation techniques and attention to detail, the panels create a seamless and visually appealing roof surface. The installation site should be prepared in accordance with the manufacturer's guidelines, and professional installers should be engaged to ensure the panels are installed correctly for optimal functionality and longevity.

6:Over Lap Type PIR PU PUF Roof Sandwich Panels Project Cases

Over Lap Type PIR PU PUF Roof Sandwich Panels are widely used in various construction projects, providing excellent thermal insulation and structural integrity. These panels have been successfully applied in numerous project cases, including commercial buildings, industrial facilities, warehouses, and residential constructions. The over lap design ensures a seamless and secure connection, enhancing the overall performance of the roof system. With their high-quality PIR PU PUF core and durable construction, these panels deliver superior thermal efficiency, moisture resistance, and fire protection. The project cases demonstrate the reliability and effectiveness of Over Lap Type PIR PU PUF Roof Sandwich Panels in meeting the demanding requirements of modern roofing applications.

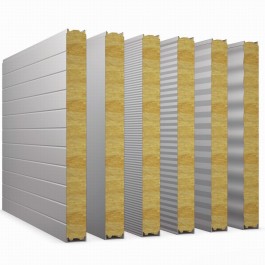

Next: Rock Wool Roof Sandwich Panel with PU Edge Sealing