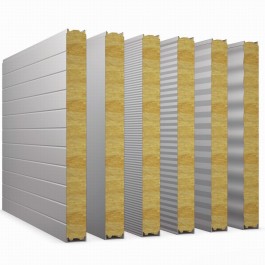

1:Parameters for Glass Wool Wall Sandwich Panels

| Steel Outer Layer | Common Thickness(mm) | Outer Panel Specs 0.6-0.8(Coated Steel Panel) |

| Outer Panel Specs 0.4-0.7(Coated Steel Panel) | ||

| Common Length(mm) | ≤12000 | |

| Common Width(mm) | 1000 as usual | |

| Coating | PVDF/SRP/HDP/PE | |

| Insulation Core | Core Material | High-quality thermal insulation,fireproof and waterproof glass wool |

| Density(kg/M3) | Glass Wool≥64;PU(Edge Sealing)≥38 | |

| Thickness(mm) | 50-150 | |

| U value(w/m·k) | Glass Wool: ≤ 0.042 PU (Edge Sealing): ≤ 0.026 | |

| Fireproof Rating | Glass Wool:Class A | |

| Process | Joint | 2-sided joint-Male-Female joint,PU Edge Sealing |

| Production Process | Continuous Production Process | |

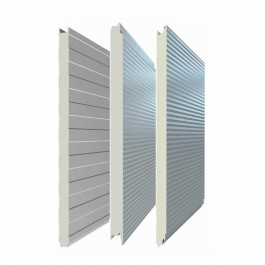

| Surface Texture | Flat/Embossed Pattern/Micro Ripple/V8 Ripple | |

| Center Trim Treatment | Connection | Metal Snap-in Cover Plate |

2:Descriptions of Glass Wool Wall Sandwich Panels

1.The A-class flame retardant rating of our High-Quality Glass Wool Wall Sandwich Panels significantly enhances the overall fire resistance of steel structures.

2.The use of polyurethane as filling material on both sides of the tongue and groove joints effectively reduces heat conduction, eliminates water leakage, and prevents moisture absorption that could compromise the strength and thermal insulation properties of the fireproof cotton, ensuring long-lasting fire protection and insulation performance.

3.The high-density core material enhances the thermal insulation performance.

4.The rigid polyurethane foam filling on both sides of the tongue and groove joints improves overall strength and prevents deformation.

5.The 90-degree rotation of the fireproof cotton ensures that the cotton fibers and panel surface are perpendicular, increasing compressive and tensile strength by over 50%.

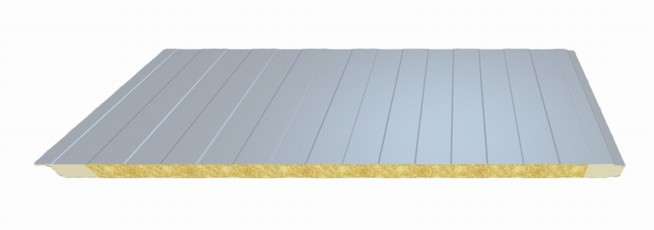

3:Production line of Hign Quality Glass Wool

Glass wool is a type of artificial inorganic fiber that belongs to the category of glass fibers. It is produced by melting natural minerals such as quartz sand, limestone, and dolomite, along with some chemical raw materials like soda ash and borax, to form glass. In its molten state, the glass is spun into fine fibers with the help of external force, creating three-dimensional interlocking and intertwining fibers with numerous small gaps. These gaps can be seen as pores, making glass wool a porous material with excellent thermal insulation and sound absorption properties.

4:Detail Treatment of PU Plug Interface of Glass Wool Sandwich Panels

5:Hign Quality Glass Wool Wall Sandwich Panels Project Cases

High-Quality Glass Wool Wall Sandwich Panels highlight successful installations in various industries, including commercial, industrial, and residential buildings. The panels' superior thermal insulation, sound absorption, and fire resistance properties have played a key role in creating energy-efficient, acoustically comfortable, and safe spaces. Each case showcases the panels' excellent structural integrity, seamless installation, and aesthetic appeal, resulting in visually appealing and high-performing buildings. With our High-Quality Glass Wool Wall Sandwich Panels, we have consistently delivered exceptional solutions that meet the unique requirements of each project, ensuring customer satisfaction and long-lasting performance.

Next: PU PUR PIR Polyurethane Insulated Wall Panels for Superior Thermal Performance