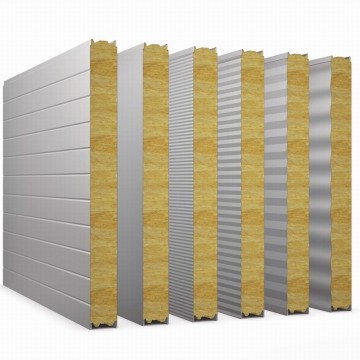

1:Parameters for Rock Wool Sandwich Wall Panels

| Steel Outer Layer | Common T (mm) | Outer Panel Specs 0.6-0.8(Coated Steel Panel) |

| Inner Panel Specs 0.4-0.7(Coated Steel Panel) | ||

| Common W (mm) | 500-1,100 | |

| Coating | PVDF / SRP / HDP / PE | |

| Insulation Core | Core Material | High-density thermal insulation, |

| fireproof and water-repellent rock wool | ||

| VW (kg/m³) | Rock Wool: ≥ 120 | |

| Thickness (mm) | 50-200 | |

| U Value (w/m·k) | Rock Wool: ≤ 0.043 | |

| Fire Rating | Rock Wool: CLASS A | |

| Process | Joint | 2-sided joint-Male-Female Joint |

| Production Process | Continuous Production Process | |

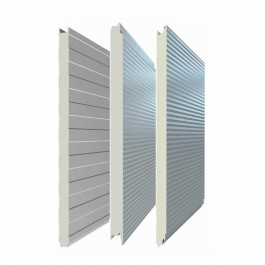

| Surface Texture | Flat / Embossed Pattern / Micro Ripple / V8 RIPPLE | |

| Center Trim Treatment | Metal Snap-in Cover Plate |

2:Rock Wool Characteristics

Rock wool is a type of mineral wool. It is a fluffy, short, and fine fiber wool made primarily from natural rocks such as basalt, diabase, dolomite, iron ore, and alumina. Processed into various products including boards, pipes, felts, tapes, and papers, rock wool finds applications in building and industrial insulation, fire protection, sound absorption, and seismic resistance.

Raw materials used in rock wool production include basalt or diabase, blast furnace slag, dolomite or limestone, among others. The main fuel sources for melting the raw materials are coke (for cupola furnaces) or electrodes (for electric furnaces).

Rock wool production also involves auxiliary materials such as thermosetting phenolic resin as a binder, and additives like de-dust oil, silicone emulsion for water repellency, silane as a coupling agent, and ammonia water.

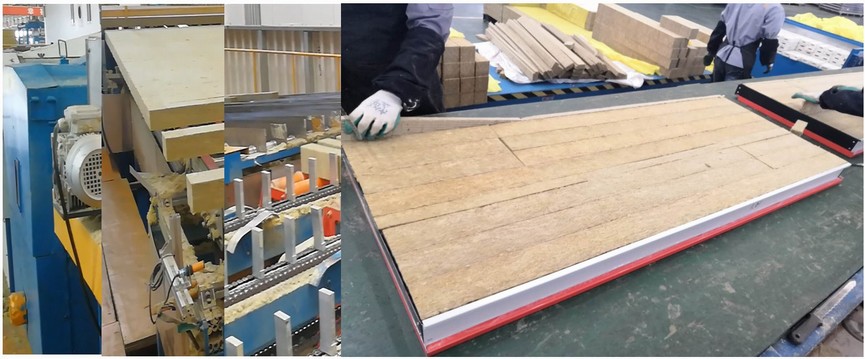

3:Production of Rock Wool Sandwich Wall Panels

Equipped for the manufacturing of high-quality Rock Wool Sandwich Wall Panels, we utilize advanced technology and processes to ensure the production of superior panels that offer excellent thermal insulation, fire resistance, and sound absorption properties. Our facility is staffed by a skilled team of professionals who oversee every stage of the production process, from material selection to panel assembly. We adhere to strict quality control measures to ensure that each panel meets the highest standards. With our state-of-the-art production site, we are committed to delivering top-notch Rock Wool Sandwich Wall Panels for various construction projects.

4:Rock Wool Exterior Wall Sandwich Panels Installation Site

5:Rock Wool Exterior Wall Sandwich Panels Project Cases

Rock Wool Exterior Wall Sandwich Panels project cases show cases the versatility and effectiveness of our products. These cases highlight successful installations in various industries such as commercial, industrial, and residential buildings. Each project demonstrates the impeccable craftsmanship and attention to detail that goes into our installations. Our panels have been utilized to enhance thermal insulation, fire resistance, and acoustic performance of exterior walls, resulting in energy-efficient and comfortable spaces. With our Rock Wool Exterior Wall Sandwich Panels, we have consistently delivered exceptional solutions that meet the unique requirements of each project, leaving our clients satisfied with the performance and aesthetics of their buildings.