1:Descriptions for Metal Warehouse Buildings

| Product name | Heavy Duty Metal Warehouse Buildings for Logistics Park |

| Main Structure | Weld H steel/ Steel Beam/Column |

| Sub-Structure | C/Z purlin,C/Z section steel |

| Roofing&Wall | Fireproof/Insulated sandwich panels or corrugated steel plate |

| Connect | By bolts |

| Lighting system | Lighting panel/aluminum alloy window/sliding window/plastic steel window/aluminum window with thermal insulation broken bridge |

| Ventilation System | Stainless Steel Ventilator |

| Door | Composite door/sliding door/rolling door/swing door/Industrial lift door |

| Certificate | CE/ISO9001/ISO14001 |

| Application | Workshop/Warehouse/Storage/Frame/Shed/Any Steel Structure Buildings |

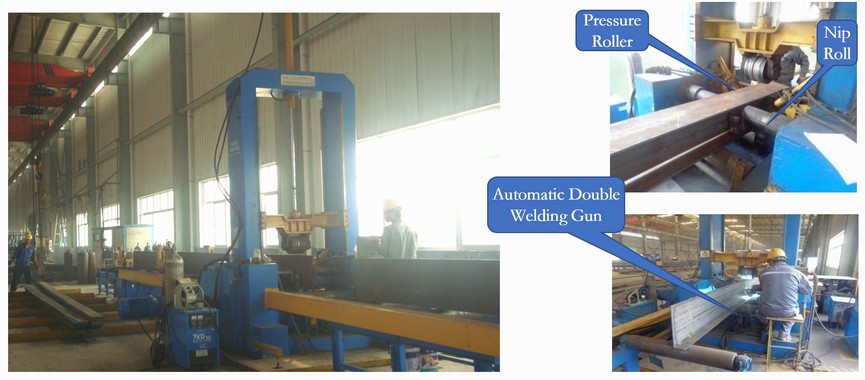

2:Steel Structure Production Production Machines

H-beam Assembly Machine is a vital equipment used for the efficient assembly of H-beams. It employs advanced technology and precision engineering to ensure accurate alignment and welding of H-beams. The machine is equipped with automated systems that facilitate the process, reducing manual labor and increasing productivity. Carbon dioxide or mixed gas, along with welding wire, is used as auxiliary materials during the assembly. Skilled operators oversee the process, ensuring the quality and integrity of the final product. The H-beam assembly machine plays a crucial role in the construction industry, enabling the fabrication of sturdy and reliable steel structures.

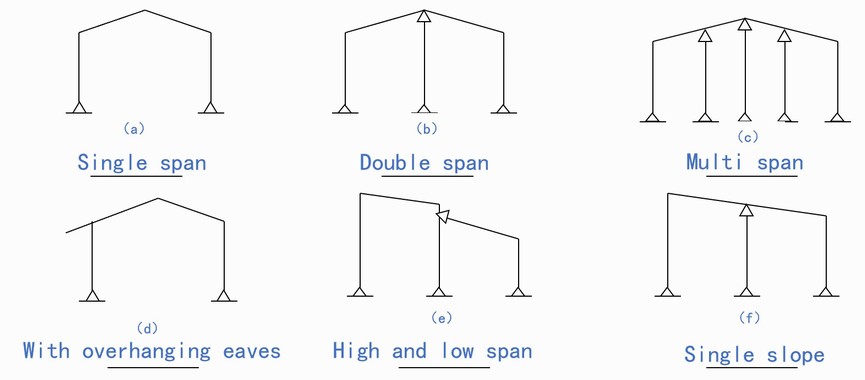

3:Portal Steel Structure Frame Types

- Single-Span Portal Frame: This type consists of a single span with a single portal frame. It is commonly used for small to medium-sized buildings.

- Multi-Span Portal Frame: This type comprises multiple spans with multiple portal frames connected in series. It is suitable for larger buildings that require wider coverage.

- Continuous Portal Frame: In this type, the portal frames are connected by continuous beams, creating a continuous structural system. It offers enhanced stability and load distribution.

- Pitched Roof Portal Frame: This type features a pitched roof, providing a sloping surface for efficient rainwater drainage.

- Curved Portal Frame: This type incorporates curved elements, adding aesthetic appeal and architectural complexity to the structure.

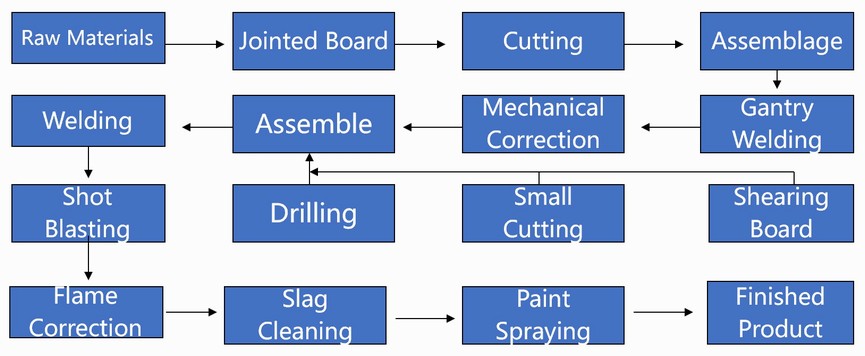

4:The production process of H-beam Steel Structures:

The production process of H-beam involves several stages to ensure the manufacturing of high-quality structural steel.

The process begins with the selection of raw materials, typically steel billets, which undergo thorough inspection for quality and composition. The billets are then heated in a furnace to reach the appropriate temperature for rolling.

Next, the heated billets are passed through a series of rolling mills. This process involves multiple passes to gradually shape the billets into the desired H-profile, including the flanges, web, and other structural elements. Precision measurements and adjustments are made throughout the rolling process to ensure dimensional accuracy.

After the initial rolling, the H-beams undergo a straightening process to remove any residual stresses and achieve straight and uniform profiles. The beams are then cut to the specified lengths using sawing or shearing techniques.

Welding is a crucial step in H-beam production. The flanges and web are welded together using various methods such as submerged arc welding or gas metal arc welding. These welding techniques ensure strong and durable connections between the components.

Finally, the finished H-beams undergo surface treatment, including cleaning, shot blasting, and painting, to enhance their corrosion resistance and aesthetic appearance. Quality inspections are conducted at various stages of the production process to ensure compliance with industry standards and specifications.

Next: Pre-Engineered Steel Frame Buildings for Electronics Factory