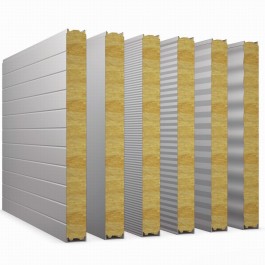

1:Parameters for EPS Sandwich Panels for Roof Systems

| Item | Value |

| Product name | EPS Sandwich Panels for Roof Systems |

| Warranty | 5--10 Years |

| After-sale Service | Online Technical Support, Onsite Installation, Onsite Training, |

| Onsite Inspection, Free spare parts, Return and Replacement, N/A | |

| Project Solution Capability | Graphic design, 3D model design, total solution for projects, Cross |

| Categories Consolidation, N/A, others | |

| Place of Origin | Shandong, China |

| Model Number | 950 |

| Core material | Rockwool |

| Colors | Customer's require |

| Thickness | 50/75/100/150/200mm |

| Length | Customer Demand |

| Width | 950mm |

| Certificate | CE/SGS/FM/ISO9001-14001 |

| Material of the facing plate | PPGI,GI, Al-Mg-Mn |

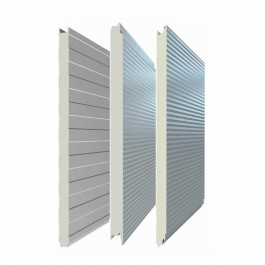

2:Details of EPS Sandwich Panels

Expanded Polystyrene (EPS) foam boards, also known as EPS polystyrene plates, are primarily made from polystyrene beads. They are lightweight, have low thermal conductivity, and provide excellent insulation properties, making them widely used in external wall insulation systems. They are used as insulation layers for building walls and roofs, composite insulation panels, insulation materials for refrigeration equipment in vehicles, ships, and cold storage warehouses, and for various decorative and sculptural models. With low thermal conductivity, high heat storage capacity, and superior insulation performance, EPS foam boards are lightweight, waterproof, moisture-resistant, corrosion-resistant, and offer easy installation and low labor costs.

3:EPS Sandwich Roof Panels Production Process

The production of EPS sandwich steel panels involves several steps. First, the steel sheets are prepared and coated with anti-corrosion materials. Then, the EPS foam core is cut and shaped according to the required dimensions. The foam cores are then bonded to the steel sheets using adhesive or through a mechanical interlocking system. The panels are pressed together to ensure a secure bond. After that, the panels undergo a curing process to strengthen the bond and enhance the overall structural integrity. Finally, the panels are trimmed and finished to achieve the desired appearance. This production process ensures the creation of high-quality EPS sandwich steel panels for various construction and insulation applications.

4:EPS Sandwich Roof Panels Installation Site

EPS sandwich roof panels are installed at various construction sites to provide excellent thermal insulation and weather protection for roofs. The installation process begins with the preparation of the roof structure, ensuring a stable and level surface. The panels are then placed and secured onto the roof using appropriate fasteners, ensuring a tight and seamless fit between panels. Proper sealing and flashing techniques are employed to prevent water penetration and ensure a watertight installation. The lightweight nature of EPS panels makes the installation process relatively easy and efficient, reducing labor and construction time. Overall, EPS sandwich roof panels offer a cost-effective and energy-efficient solution for roofing applications.

5:Common Q/As of EPS Sandwich Roof Panels

- Q: Are EPS sandwich roof panels waterproof?

A: Yes, EPS sandwich roof panels are designed with waterproofing features to prevent water penetration and ensure a dry and leak-free roof. - Q: Can EPS sandwich roof panels withstand harsh weather conditions?

A: Yes, EPS sandwich roof panels are durable and can withstand extreme weather conditions such as rain, snow, and high winds. - Q: Are EPS sandwich roof panels suitable for both residential and commercial buildings?

A: Yes, EPS sandwich roof panels are versatile and can be used in various applications, including residential and commercial buildings. - Q: Can EPS sandwich roof panels help with energy efficiency?

A: Absolutely, EPS sandwich roof panels provide excellent thermal insulation, reducing heat transfer and improving energy efficiency. - Q: Are EPS sandwich roof panels environmentally friendly?

A: Yes, EPS sandwich roof panels are made from recyclable materials and contribute to reducing energy consumption, making them an eco-friendly choice.

Next: Snap Cap Glass Wool Roof Sandwich Panel