1:Parameters for Closed Type Hot Galvanized Steel Floor Decks

| Product Name | Closed Type Hot Galvanized Steel Floor Decks for Multi Story Buildings |

| Capacity | 100,000 square meters/month |

| Certificate | ISO9001~14001 |

| Material | Q235/Q235B/Q345/Q345B/SS400 |

| Connection Form | Bolt Connection |

| Type of Steel For Building Structure | High-Strength Steel |

| Steel Sheets Thickness(mm) | 0.75-1.60 |

| Zinc Coating(G/M2) | 120-350 |

| Application | Steel Workshop, Steel Structure Platform, Steel Fabricated House, Structural Roofing, Steel Walkway and Floor, Steel Structure Bridge, High Rise Building/Duplex Structure |

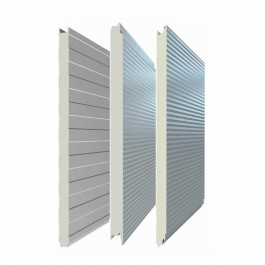

2:Details of Closed Type Hot Galvanized Steel Floor Deck

Closed type hot galvanized steel floor decks are highly reliable and efficient flooring solutions used in various construction projects. These floor decks offer several advantages, including exceptional strength, durability, and fire resistance. The hot galvanized coating provides excellent corrosion protection, ensuring a longer lifespan and reduced maintenance requirements.

With their closed design, these floor decks provide enhanced structural stability and load-bearing capacity. They are suitable for applications that require a solid and secure flooring system, such as high-rise buildings, industrial facilities, and commercial structures.

Closed type hot galvanized steel floor decks are available in different profiles and thicknesses, allowing for customization to meet specific project needs.

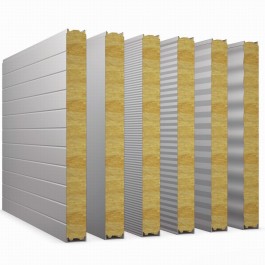

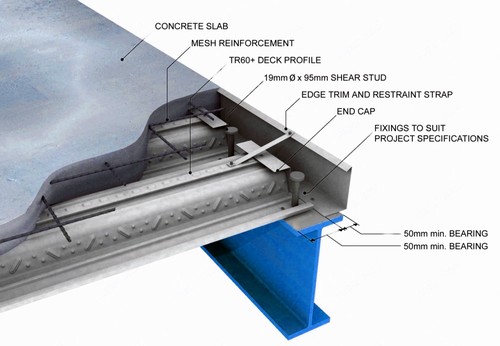

3:Layers of Steel Floor Decks

Steel floor decks consist of multiple layers that work together to provide a strong and stable flooring system. The layers typically include the structural steel support beams, the steel floor deck panels, and a concrete topping.

During installation, the structural steel beams are first placed and secured to provide the framework for the floor. The steel floor deck panels are then laid over the beams and fixed in place. Finally, a layer of concrete is poured and cured on top of the floor deck panels, creating a solid and durable surface.

This multi-layered approach offers several benefits, including increased structural integrity, enhanced load-bearing capacity, and improved fire resistance. It is a reliable solution for various construction projects, from commercial buildings to industrial facilities.

4:Closed Type Hot Galvanized Steel Floor Deck Production Machines

Closed type hot galvanized steel floor deck production machines are advanced equipment used in the manufacturing process of steel floor decks. These machines are specifically designed to produce high-quality floor deck panels with a closed profile and hot-dip galvanized coating for added durability and corrosion resistance.

The production machines utilize cutting-edge technology and automated processes to ensure precise and efficient manufacturing. They can handle various thicknesses and dimensions of steel sheets, allowing for flexibility in design and customization. The machines are equipped with features such as roll forming, cutting, punching, and stacking mechanisms to produce finished floor deck panels ready for installation.

5:Closed Type Hot Galvanized Steel Floor Deck Project Cases

Closed type hot galvanized steel floor deck project cases showcase the successful implementation of these durable and reliable floor systems in various construction projects. These projects highlight the versatility and performance of closed type hot galvanized steel floor decks in applications such as commercial buildings, industrial facilities, and residential constructions.

The project cases demonstrate the effectiveness of these floor decks in providing structural stability, fire resistance, and sound insulation. They also emphasize the efficient installation process and the long-lasting performance of the floor systems. With their excellent load-bearing capacity and corrosion resistance, closed type hot galvanized steel floor decks offer a cost-effective and sustainable solution for modern construction projects.

Next: Steel Framing Purlins Girts Z Section Purlins Z Shaped Steels